News

11. May 2025

3 minutes read time

Tailor-Made for Diagnostics: Custom Injection-Molded Solutions by Fischer Söhne AG

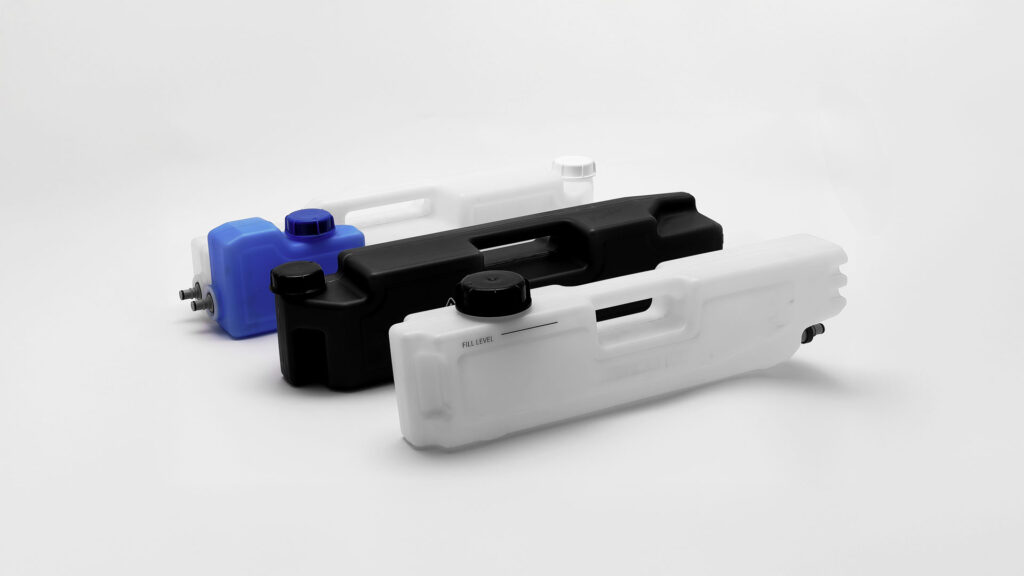

Muri, 14 May 2025 – With a longstanding reputation for excellence in plastics processing, Fischer Söhne AG continues to be a trusted partner to the healthcare industry. Drawing on extensive expertise, the company delivers high-quality, tailor-made injection-molded components and extrusion-blow-molded printed containers for diagnostic applications. These solutions stand out for their precision, operational efficiency, and user-friendly design – ensuring smooth handling in day-to-day laboratory workflows.

Why Customization Matters in Diagnostics

In the fast-paced and highly sensitive world of medical diagnostics, standardized solutions often fall short. Every detail matters: from precise fit and chemical resistance to intuitive handling and seamless integration into automated systems. Thoughtful design enhances safety, minimizes user error, and simplifies daily operation.

Customization allows medical device and diagnostics manufacturers to overcome these challenges while meeting rigorous industry standards. At Fischer Söhne, bespoke solutions ensure that each product aligns perfectly with client needs and end-user expectations.

Fischer Söhne’s Diagnostics Expertise

With decades of experience and a deep understanding of diagnostic requirements, Fischer Söhne AG develops and manufactures customized plastic components and containers for leading companies in the healthcare sector. The foundation of this capability lies in highly efficient and scalable manufacturing processes:

- Injection Molding Excellence: Fischer Söhne manufactures precise, high-quality components in large volumes. The process supports various materials, ensures excellent surface finishes, and enables cost-efficient, low-waste production through automation.

- Efficient Extrusion Blow Molding: Ideal for hollow containers, this process ensures precise wall thickness and low material use, which is cost-effective for both large and small production runs.

- In-House Decoration: Functional and visually clear screen printing is carried out internally, enhancing usability and branding while streamlining the production process.

- Hygiene-Focused Production: Our extrusion blow molding takes place in a BRC-certified environment, ensuring high hygiene standards for thermoplastic packaging used in food, beverage, and sensitive applications.

- Sustainable Materials: Fischer Söhne uses recyclable materials and designs processes that minimize waste – combining environmental responsibility with technical precision.

Key Advantages for the Healthcare Industry

- Tailor-Made Solutions: Products are developed based on specific requirements, ensuring optimal fit, function, and integration into diagnostic systems.

- Reliable Performance: Thanks to robust engineering and controlled production environments, Fischer Söhne’s solutions maintain consistent quality, even under demanding conditions.

- Efficient Assembly and Delivery: Fully assembled products and just-in-time logistics simplify supply chains and reduce operational overhead.

- User-Centric Design: Products are optimized for easy handling, clear identification, and intuitive use – supporting safe, efficient workflows for end users.

Partnering for Success

Fischer Söhne’s customer-focused approach emphasizes close collaboration. Clients benefit from a full-service offering – from engineering and toolmaking to decoration and assembly – all under one roof. This end-to-end capability ensures faster time to market and maximum flexibility.

Contact Information

Ready to shape your path to success? Contact Fischer Söhne AG today to learn more about our solutions and how we can support your business.

About Fischer Söhne

For over a hundred years, Fischer Söhne has been a trusted name in the packaging industry that stands for reliability and quality. With a strong focus on precision, innovation, and customer satisfaction, Fischer Söhne is committed to supporting the pharmaceutical industry with state-of-the-art products and complex plastic container solutions. By leveraging decades of experience and a deep understanding of industry trends, Fischer Söhne can help its partners to meet the highest standards while driving operational excellence.

See our other content

/10